Environmental considerations have always been taken into account in the research and development activities of the process industry, at least where related to process efficiency.

But true environmental awareness in the industry has only emerged during the last five years. Before that, it was often just pretty words.

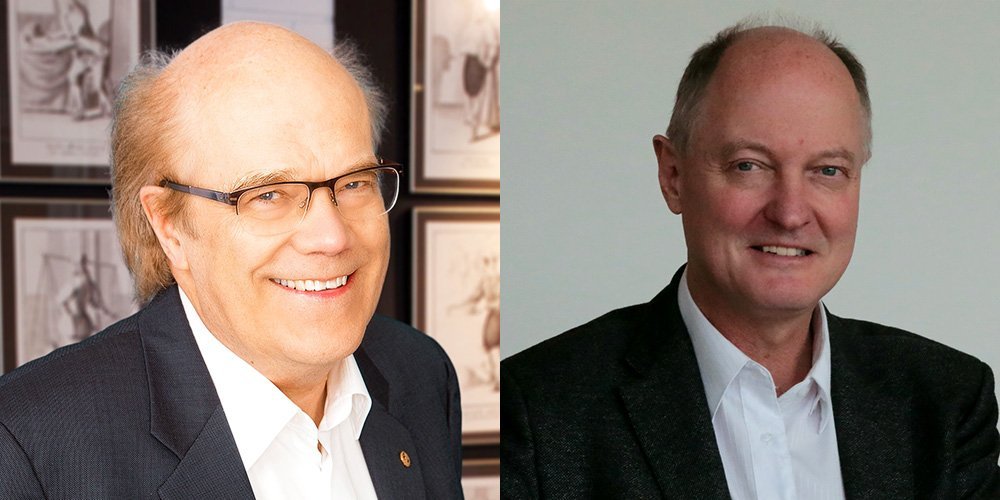

This is the opinion of Antti Roine, Technology Director of the Modeling and Simulation department at Metso.

Life-cycle assessments, or LCAs, of environmental impact have typically been conducted by outsourcing the task to a sustainability consultant with tools and average figures designed for the purpose.

"LCA tools have often been designed by people other than engineers who do not necessarily understand the physics and technological detail of the field, and therefore, things may get simplified to a level where the produced indicators may not be based on physics and reality. These are necessary for the metallurgical industry to innovate toward a greener future, and HSC Sim makes this possible if integrated with LCA," explains Markus A. Reuter, an honorary professor at TU Bergakademie Freiberg.

HSC Sim is a process simulator specifically designed for the mining industry, but also suitable for use in other sectors. The aim has been to develop a simple yet powerful simulation tool for ordinary process engineers. It can be used to simulate nearly all kinds of processes.

Today's process industry is interested in actual LCA figures. Customers, society, legislation, and social media are pushing us to take environmental issues seriously.

As an industry, we must become more transparent about our environmental impact."

"When an outsider asks a company for data, the company can be disinclined to provide all the information. As an industry, we must become more transparent about our environmental impact. Using, for example, HSC Sim as a tool, companies can utilize their detailed process knowledge to obtain specific footprints for their operations, thereby leading the discussion and reducing their dependency on external consultants. Furthermore, using the tools for larger system analysis in the circular economy, more realistic efficiencies can be estimated both in terms of recoveries, footprints, and exergy," Reuter notes.

HSC Sim is a process simulator specifically designed for the mining industry, but also applicable to other sectors. The aim has been to develop a simple but powerful tool for ordinary process engineers. It can be used to simulate nearly all kinds of processes.

Powered by decades of experience

Reuter and Roine are pioneers in LCA, having collaborated for a long time.

Roine has been involved in developing the HSC Chemistry software for decades. The software was originally designed for the research and development needs of the process industry. Still, it has since been utilized for process planning and optimization of process operations as well.

Reuter, on the other hand, has a long history of studying and performing environmental footprint calculations: the first hand-calculated but scientifically valid footprint estimate was made for a German copper producer in 1993. In 2007, Reuter suggested to Roine, who were both working at Outotec at the time, that environmental impact LCAs as well as exergy could be integrated into HSC Chemistry.

"Markus was fairly persistent about it. In 2011, Outotec received funding for the project, and since 2020, we've had a software that can be used in process planning, as a digital twin engine, and for calculating environmental footprints," Roine recalls.

Efficient process operation saves both energy and raw materials, improving both sustainability and profitability."

Roine and Reuter list pioneering companies with whom they have collaborated in the past, including copper producers Aurubis and KGHM, mining, smelting, and metal recovery company Boliden, and Roine's employer, Metso, a metals processing technology expert.

Including LCAs in process planning and process operation makes it easier to combine the positive environmental impacts with more efficient business operations, especially in quantifying what is carbon-neutral. In addition, the combination of the LCA tool and exergetic analysis, as included by Roine and Reuter in HSC, makes this a powerful combination for fully understanding the limits of systems, as well as metallurgical processing technology and flowsheets.

"Efficient process operation saves both energy and raw materials, improving both sustainability and profitability. Typically, if you can improve process efficiency, you can also recover more metals and consume less energy and water," observes Roine.

Unique process, similar unit operations

In the process industry, particularly in metallurgy, which focuses on metal production and refining methods, almost every process is unique. The properties of the raw materials used vary depending on their origin.

But all processes consist of similar unit operations. Modelling is possible when the software knows the individual building blocks and how to calculate the elemental, energy, and exergy balances.

"Process efficiency will depend on the quality of the raw materials, which is why a designated process model is required for each process," Roine emphasizes.

Common LCA tools are difficult to apply to processes that do not exist, whereas, according to Roine, the HSC software enables the utilization of the environmental footprint to optimize both existing processes and those of new factories.

Situations vary from case to case, but Roine estimates that the software has the potential to decrease the environmental impact of a continuously running process by approximately 30% and that of a completely new factory by up to 90%. At the same time, it helps reduce the consumption of, for example, raw materials, energy, and water by increasing process efficiency.

"Emission reductions in a new factory will succeed if the factory is sensibly designed and cycles are closed. It is both more efficient and environmentally friendly to have process water flow in a closed circle instead of always taking new water in from the river and recirculating it back to nature after use, for example."

When discussing the environmental impacts of the products from the process industry's life cycle, calculations must include the users of these products, specifically the goods-producing manufacturing industry and the recycling of these goods. There is still a lot of work to be done here, both in terms of accurately calculating environmental impacts and ensuring recycling is handled as efficiently as possible.

Efficient recycling at the elemental level

"Cars, mobile phones, and other goods cannot be recycled as they are, but the process industry has systems in place for reusing their materials. Recycled metals can be utilized down to the elemental level; for example, gold is often produced as a by-product of the copper industry," Roine points out.

Reuter has designed the Metal Wheel diagram, which provides a quick overview of what happens to various metals in base metal manufacturing processes. The sectors in the diagram show how valuable metals behave in each main process.

The majority of valuable metals in scrap and waste can be recovered by correctly sorting recyclable materials.

For example, precious metals are well-suited for recycling at copper, zinc, or nickel plants, but they are of no use to the steel industry.

"Recycling planning is currently nowhere near its full potential," Reuter points out.

He takes the A-frame of a car as an example. The main material of the part is a variety of different steel types, but other materials are added to it to make it lighter.

"These materials must be separated for recycling, for example, by shredding. Incomplete liberation results in material losses, which can be directed to incorrect downstream processing. This waste/residue is usually not accounted for in normal design for recycling, as it is too demanding for these more simplistic approaches. Still, the HSC software can provide information on the actual quantity of these losses."